Light Gauge Steel Framing Fabrication Processes & Drawings at Fab Shops

Fabrication of light gauge steel framing is a process that uses raw materials such as light weight structural steel and light gauge steel to turn it into an object with a specific design and function used in buildings and building parts. Such fabricated items may have other uses besides in construction like in furniture, model & etc.

The process of steel frame construction is carried out in special manufacturing units equipped with requisite tools and machinery. The processing units are called fab shops.

The process usually includes:

House floor plan

House detailing designed

Drawing

Cutting

Punching

Bending

Shearing

Depending upon the purpose of fabrication, aligned process may also come into picture using higher technologies, machine and tools for steel frame construction.

Once the components are made they may be assembled to form one productive unit used in the building. The assembling process may involve screw & connector connection. Next steps would be packed via the mark number on each profile and tight them well.

Popular use of fabrication technology of cold formed metal framing is to make building components which are usually single components built at a fab shop and installed at construction site.

The use light weight structural steel, prefabrication technique employed at fab shops and subsequent installation at place of work nearby all accord monetary gains or benefits making the business profitable.

Not only components but structural steel work may also be used to make a skeletal frame of the building.This frame usually consists of light gauge steel framing, and some projects with complicated structure or as per the customers’ requirement will use columns and beams made from hot rolled steel which is bolted or riveted or welded together.

Light gauge steel framingDrawings

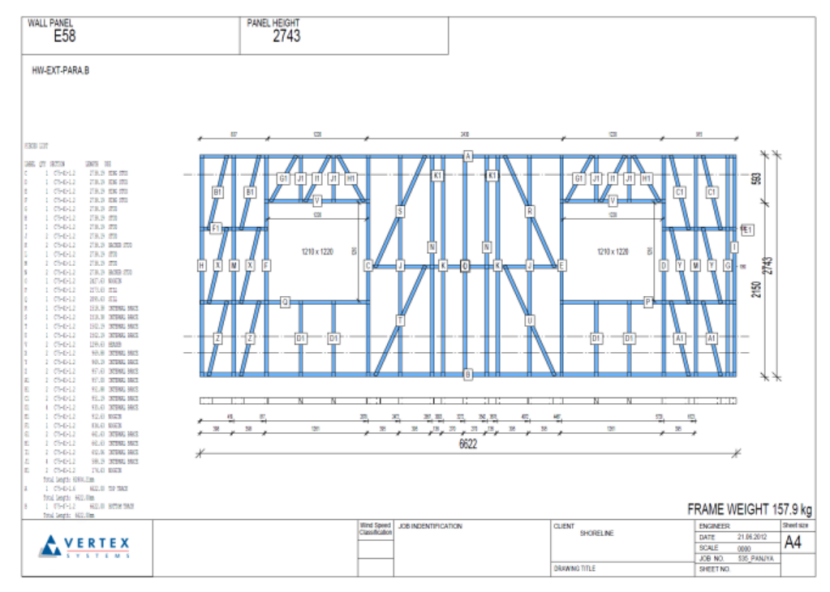

The initial step involves component drawings which usually describes the parts that comprise the unit. In the drawings specifications or component dimensions and physical and chemical properties may be highlighted. The mention of properties highlights the quality which is very important aspect of this business.

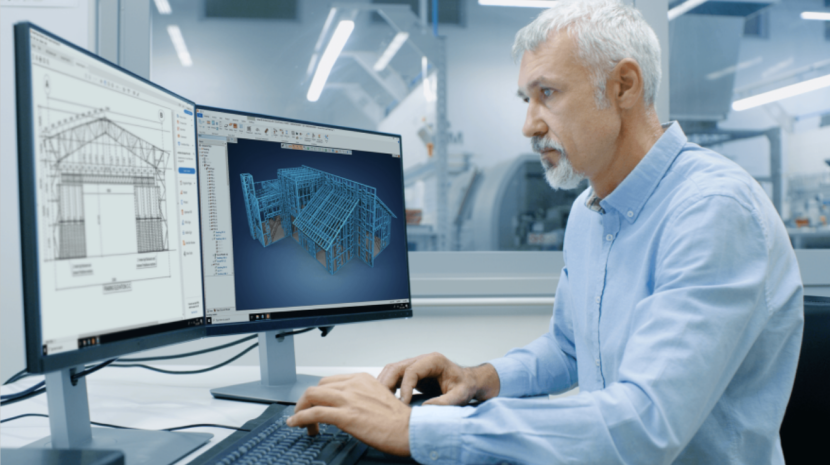

When more than one component is involved, it is called assembly and the assembly drawing refers to the components. The drawings are made regarding all aspects of building construction. The drawing are made using CAD software or other open source advance software.

The fabrication drawing are comprehensive and not just simple diagrams or lines. They provide detailed descriptions and specifications and a list that identifies all materials used. The drawing notes should clarify the stress relieving requirement, also it can give the calculation of the total weight & length of the steel framing.

Fab shops thus are comprehensive units in modern times with amalgamation of many technologies including computerization. In order to fabricate building components quality steel fabricators follow a strict methodology. The business has over the number of years become very competitive but rewarding.

© Copyright 2024 Buildmart (Xiamen) Building Material Technology Co., Ltd.. All Rights Reserved.

IPv6 network supported

Friendly Links:

Scaffold Supplier