The Benefits of Steel-VS-Wood for Low-Rise Building Construction

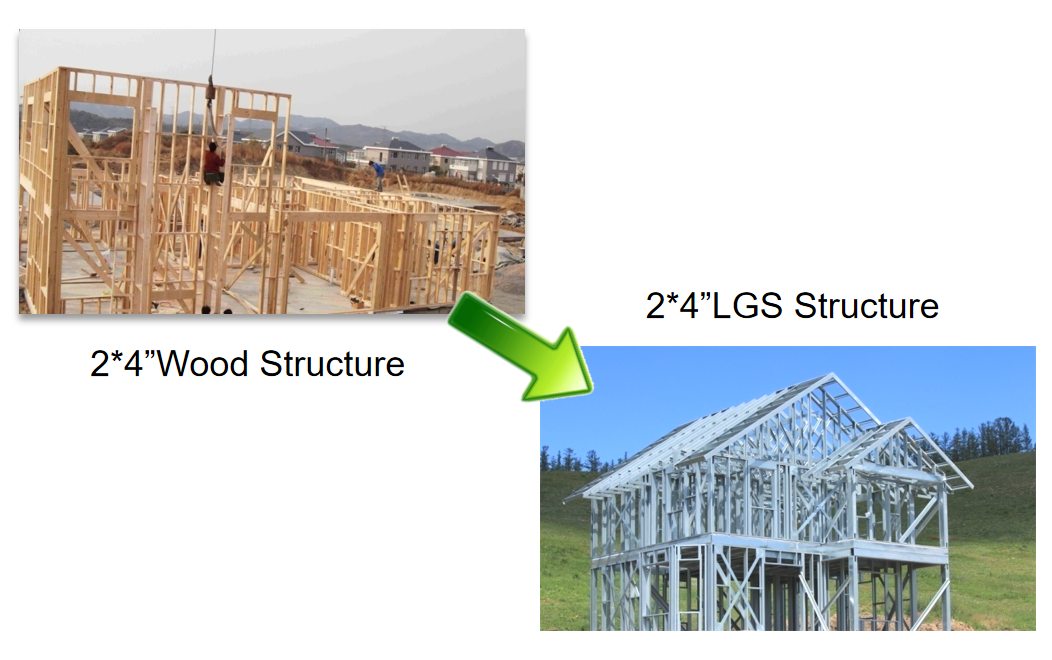

Origin of LGS Structure

• It is derived from the construction technology of balsa wood structure and follows the construction method of 2*4 wood structure;

• Using galvanized steel sheet with thickness of 1.0mm-2.4mm to roll cold-formed thin-walled steel skeleton;

• The keel interval of the wall endurance structure (C-section steel) is 406mm or 610mm;

• A variety of cladding materials are covered on the basis of the light steel structure, which greatly provides the habitability and aesthetics of the building.

Sustainability, durability, fire resistance, structural performance and cost-effectiveness are some of the strongest reasons for using metal building systems in low-rise building construction. As a dependable, noncombustible material, steel-framed structures provide a wise investment for builders and the occupants who live and work in them.

Steel structures provide long-term, consistent performance.

Steel framing will not rot, warp, split, crack, or creep. Steel framing is not vulnerable to termites. Steel framing does not expand or contract with moisture content. Steel framing is produced in strict accordance with national standards, and no regional variations.

Steel is a noncombustible material and will not contribute to the spread of a fire.

Because steel is noncombustible, it reduces the fire risk to occupants, firefighters, and property/business owners.

Steel framing improves design efficiency, saves time, and reduces costs.

Steel framing provides a significantly greater strength-to-weight ratio than wood. Steel framing allows for larger bays and wider frame spacing than wood construction.

Increased flexibility in bay spacing and framing layout maximizes usable floor space for owners and tenants. Steel is typically fabricated off-site, reducing on-site labor, cycle time, and construction waste. Shorter construction time results in earlier occupancies and lower financing costs.

Steel structures perform well during earthquakes and other extreme events.

Steel is a resilient material, with reserve strength and ductility that result in significant advantages in natural disasters such as hurricanes and earthquakes, and in other extreme events like fire and blast. Steel construction is engineered to provide a reliable, consistent load path. Steel construction employs quality control and quality assurance procedures to ensure that the project requirements are met.

Steel framing provides environmental benefits and complies with sustainable building standards.

Steel framing results in less scrap and job site waste than lumber. Structural steel is continually recycled with a current recycling rate of 98 percent, meaning that these steels will still be in use hundreds of years from now, lessening impacts on future generations. Steel, when recycled, loses none of its inherent properties and can be recycled into different products such as cars, bridges, cans, etc. Steel can be used to comply with the requirements of sustainable design standards such as the International Green Construction Code (IgCC), ASHRAE Standard 189.1 (Standard for the Design of High-Performance Green Buildings Except Low-Rise Residential Buildings), and the National Green Building Standard (ICC-700). Steel can also provide credit points for green building rating systems like the USGBC’s LEED (Leadership in Energy and Environmental Design) and the Green Building Initiative’s ANSI/ GBI-01 (Green Building Assessment Protocol for Commercial Buildings).

If you are interested, pls contact BuildMart at www.buildmartmaterial.com.

© Copyright 2024 Buildmart (Xiamen) Building Material Technology Co., Ltd.. All Rights Reserved.

IPv6 network supported