Do a Good Job in the Details of the Internal and External Corners of the Cement Fiber Board Exterior Wall

How to Detail a Perfectly Seamless Fiber Cement Board–Clad Corner

Creating a seamless corner detail isn’t as difficult as you think.

Fiber cement cladding is not as difficult to detail as you think. Architects use it successfully for a wide variety of applications because it’s cheaper than other cladding materials, can be fabricated to look like a variety of raw materials (such as wood or concrete) and can envelop your most basic multifamily unit complex, a pastiche piece of residential design or a monolithic otherworldly structure. It’s all about versatility in shape, texture, color and manipulation.

That said, one challenge that has long plagued architects and contractors alike is the art of creating a seamless corner on a fiber cement–clad building. Big-box architecture and smaller-scale residential constructions often call for perfectly flush corner details that can be effortlessly installed.

The idea is to make sure the sheets of fiber cement don’t “end” or break at the point the building’s shape changes or abut a secondary vertical element at the corner. In the ideal scenario, there should be no tacky protruding product such as steel or vinyl attached to the corner, protecting it from the elements.

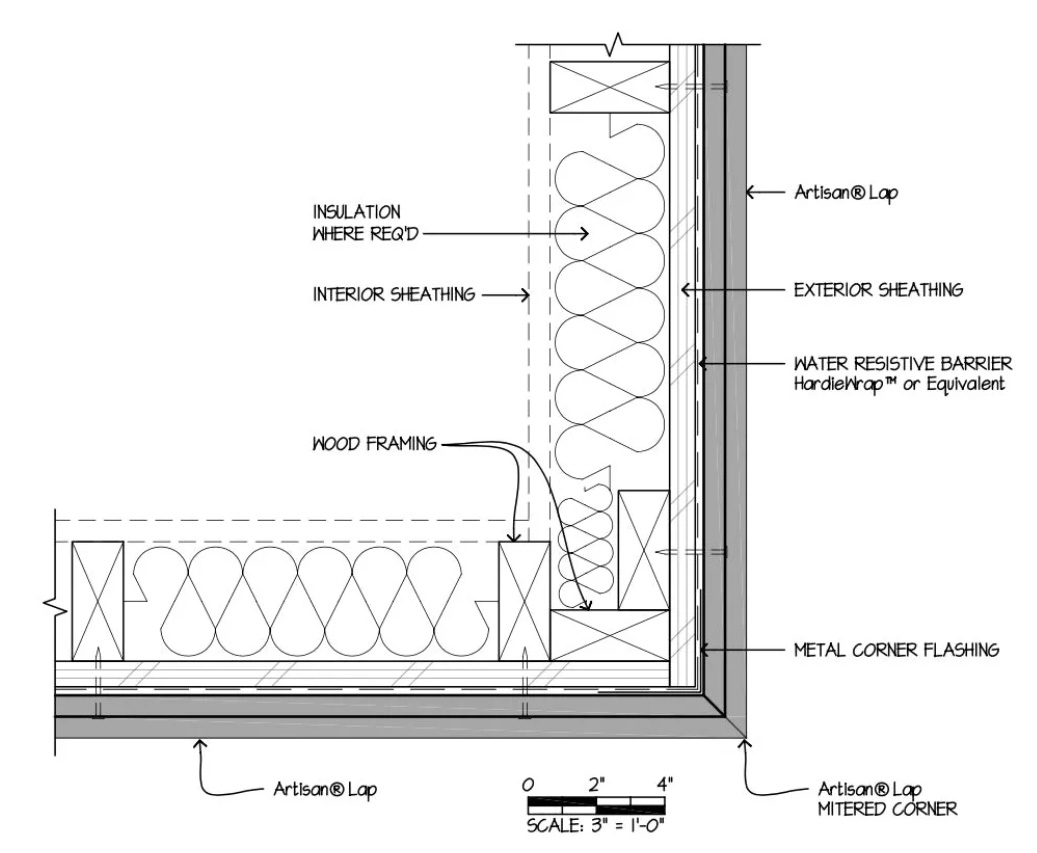

There are several companies whose refined cladding techniques help achieve this look. James Hardie Building Products, a fiber cement paneling manufacturer and inventor of the Hardie board, offers details on how to produce mitered corners: joints made from two pieces of beveled material that create a neat 90-degree angle.

To detail a mitered outside corner using James Hardie’s Artisan® Lap Siding, a robust interior corner must first be constructed. Behind the fiber cement sheeting should be a breathable waterproof membrane by exterior sheathing and then an air gap with small wooden spacers screwed into the corner. Depending on the outline of the project and the size of fiber cement planks used, the tougher the interior corner structure will need to be.

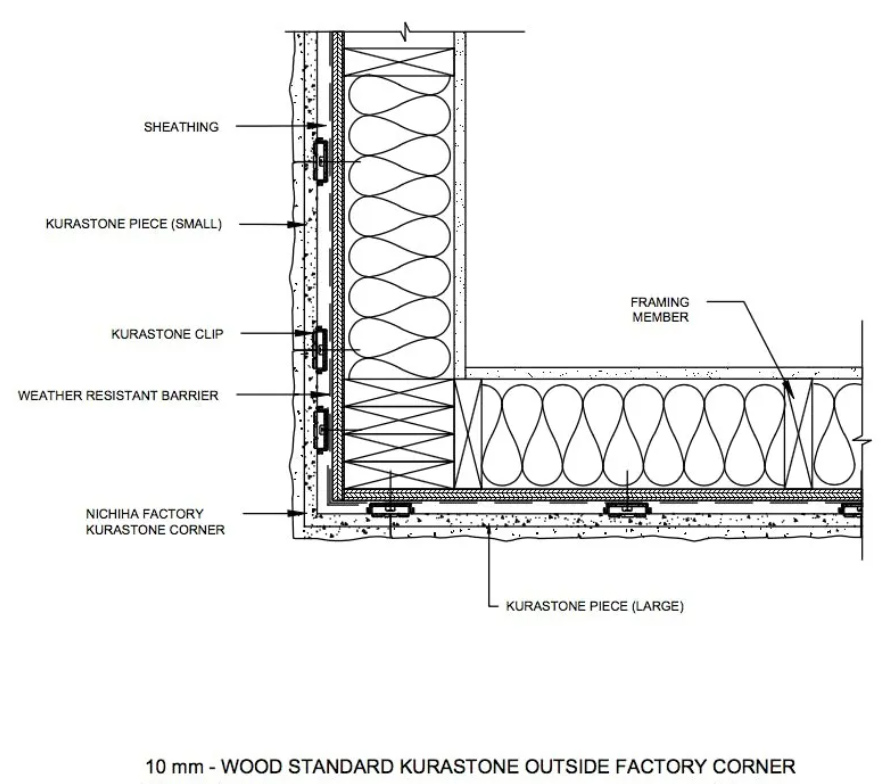

This concept is brilliant when it comes to creating a continuous horizontal “wrap” around a building, emphasized from a distance with the use of shadow gaps. Because fiber cement is considered more durable and long-lasting than wood, which might rot or fade, this is the ideal application for creating the appearance of an uninterrupted pattern on an external façade.

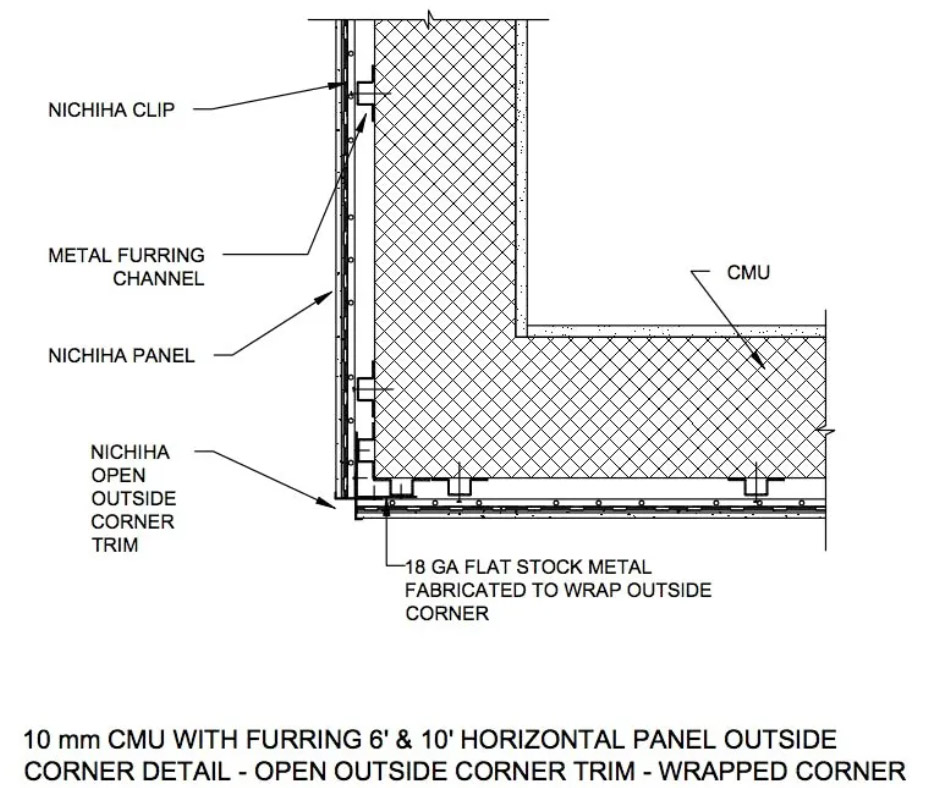

Nichiha, a Georgia-based fiber cement company, also offers mitered corners with a 3.5-inch return in their product line. This feature is available in the same finishes as all of their horizontal architectural wall panels; we’re talking fiber cement made to look like brick, wood or even sandstone, all with a virtually seamless corner detail.

They also offer a specialty corner product called NichiTrim, which can be used in a single or double corner trim method. It has classic residential appeal, but it doesn’t get you the look of a consistent façade using a single material.

EQUITONE, a major fiber cement brand that is popular with big-name architects, features a continuous, vertical cavity closer within its ventilated, façade rainscreen system. This invisible structural insert stabilizes the panels from wind pressure with extra support.

No matter the size or length of fiber cement planks or panels on a project, this versatile and weatherproof material is a strong substitute for other types of cladding products. While it is cheaper than metal, concrete and stone, it can look high-quality and expensive with well-considered, seamless corner detailing.

© Copyright 2024 Buildmart (Xiamen) Building Material Technology Co., Ltd.. All Rights Reserved.

IPv6 network supported